Description

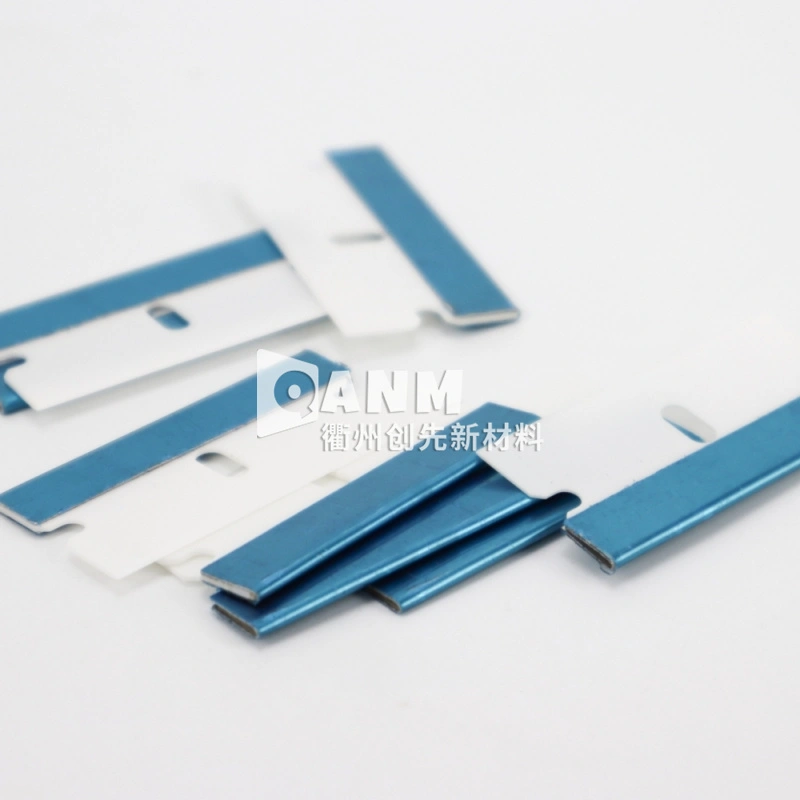

We are ceramic blade factory

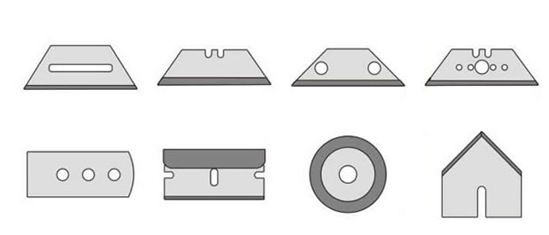

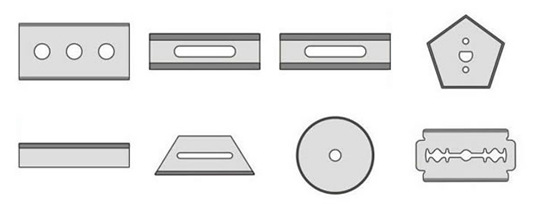

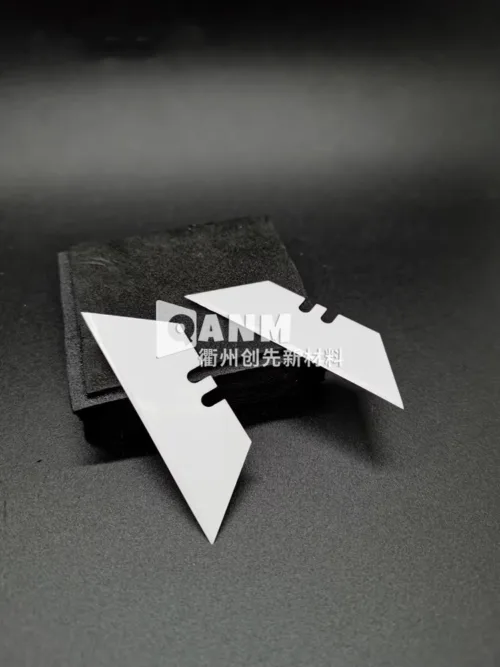

Ceramic blades show,just a part of them

Company Introduction

QuZhou Advanced New Material Co.Ltd is a professional manufacturer of zirconia ceramic products in China.We are committed to subverting traditional industrial blades.

QANM have 3 main products: ①zirconia ceramic blades ②zirconia ceramic rods&sheets ③ zirconia ceramic machined components.

The wear resistance of ceramic blades is 6-10 times that of metal blades. With less blade replacements and higher production efficiency. Low friction coefficient, smooth cut surface without pilling. Ceramic blades, with their excellent heat resistance, wear resistance, chemical stability, and no electrostatic loading, have demonstrated unparalleled advantages over traditional cutting tools in the field of high-speed cutting and cutting difficult to machine materials.

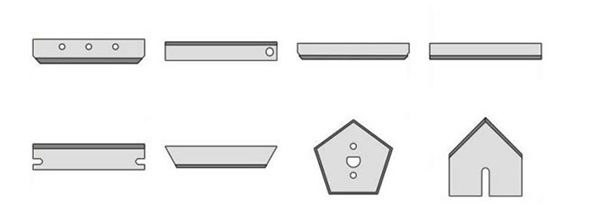

Main product categories

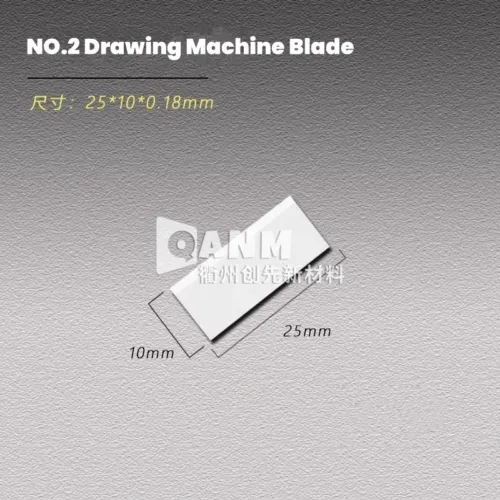

1 Cutting Machinery Series Blades

Mainly used for cutting chemical fibers and glass fibers, paper tape, adhesive tape, magnetic tape, and film

The thinnest thickness is 0.15mm

The fiber cutting length is precise and will not scatter

Less blade replacement times, longer machine operation time, and higher production efficiency

2 Industrial textile blades

Mainly used for slicing various types of textiles

The thinnest thickness is 0.15mm

Will not cause fiber melting, thereby reducing losses caused by starting and stopping

The blade is durable, which improves production efficiency and shortens production assistance time

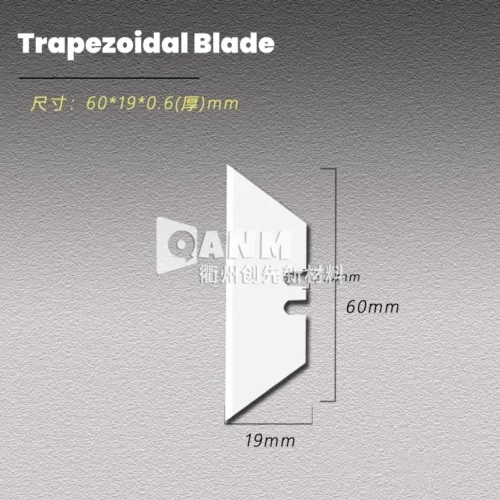

3 Various high-performance thin zirconia ceramic blades

Some application fields constantly demand higher and more special requirements for blades, such as medical technology, electronics industry, etc. Ceramic blades are the best blades to meet these requirements

Extremely high corrosion resistance performance

Non static loading has a service life 50-100 times longer than ordinary steel knives and 3-13 times longer than hard alloys

Reviews

There are no reviews yet.